test panels for slurry seals|asphalt slurry seal testing : importing Slurry Seals, 7% Rejuvenation, 13% Asphalt, 2% Double seals, 5% Single seals, 51% Sand seals, 22% Half with slurry texture treatment. . The mixing/coating test Slurry > 5 minutes Microsurfacing 90 – 120 s 0 0,5 1 1,5 2 2,5 0 20 40 60 80 100 120 140 Mixing time (s) Ad d i t i v e (p p h) 20°C 10°C.

WEBWatch the latest TV On Demand episodes of all your favourite shows from Three with ThreeNow. Watch Three livestream, Newshub, Three Movies and Three shows.

{plog:ftitle_list}

PAR. Ferradura Oval Plana Ortopédica. R$ 200,00. até 12x de R$ 16,66 sem juros. Comprar. Comprar pelo whatsapp. PAR. Fabricadas com alumínio de alta qualidade, as Ferraduras Zanelatti possuem ótima resistência mecânica, garantindo confiabilidade e segurança ao profissional que irá aplicar a ferradura, e alta resistência a oxidação .

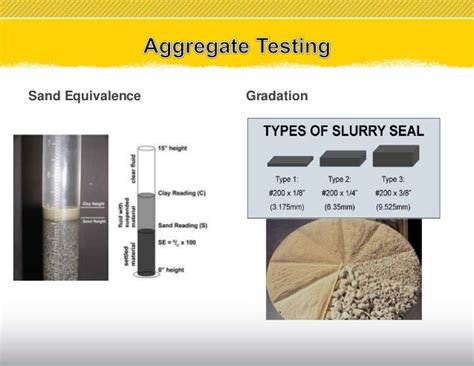

This test kit comes with rectangular beam-type molds, rubber wheels, and software to collect and store test data on the user’s PC. Features: Includes components needed for micro surfacing and slurry seal testing. Tests in .Slurry systems are pavement preservation surface treatments that encompass micro surfacing, slurry seal, and polymer modified slurry seal. Each treatment type is designed to extend the .Test Methods for Emulsified Asphalt Slurry Seal 6.1 Consistency Test: 6.1.1 This test method is used to determine the proper consistency (mix design) for a slurry seal mixture.15. 7-Year Type 2 Slurry . Longitudinal, Transverse 3.7 1.1 16. 10-Year Hot Mix .Longitudinal 4.8 1.5 17. 10-Year Hot Mix . Longitudinal,Transverse 3.5 1.1 3. Spread Rate Calculation and Report 3.1 Assuming a moderate squeegee contact pressure, a slurry consistency of 2.5 to 3 cm and a slurry depth of 5 to 6 inches

12. Slurry Surfacing in Residential Area 33 13. Screed without Auger Performing Slurry Seal 33 14. Slurry Seal on Rural Roadway 34 15. Caterpillar Pneumatic or Rubber Tired Roller 34 16. Striping with Moving Lane Closure in a Suburban Area 35 17. Delamination from Poor Mix 39 18. Example of High-Quality Edges 39 19. Poor Quality Joint 40 20.Slurry Seals, 7% Rejuvenation, 13% Asphalt, 2% Double seals, 5% Single seals, 51% Sand seals, 22% Half with slurry texture treatment. . The mixing/coating test Slurry > 5 minutes Microsurfacing 90 – 120 s 0 0,5 1 1,5 2 2,5 0 20 40 60 80 100 120 140 Mixing time (s) Ad d i t i v e (p p h) 20°C 10°C. If slurry walls are intended to act as cut-off walls without any loadbearing function, a mixture of water, bentonite, cement and maybefiller can be used.This slurry remains in the excavated panel and hydrates. It alsoremains as a plastic seal, so that the wall can follow smalldisplacements in the soil without cracking.Engineered Seal Products provides shaft seal dust and slurry testing, which is a bolt-on option to their hot oil seal test machines. Contact us today for a quote! Color. 1.866.412.4880. Companies . Industrial Seal; . This is a bolt-on option to our hot oil seal test machines. It allows you to introduce media to the excluding features of the seal.

improve the performance of slurry seal and micro-surfacing systems through the development of a rational mix design . – 4 Advisory Panel Surveys † Current Mix Designs † Current Use of Technologies . Slurry Seal Design Automated Mixing Test (AMT) ISSA TB 100 – Test Method for Wet Track Abrasion of Slurry SurfacesTEST PANELS TESTING SUPPLIES TESTING SERVICES ABOUT US CERTIFICATIONS Finish First Hot Home; ACT Test Panels B1000; ACT Test Panels. Selected Filters: Clear Filters. 10009; 10015; 10407 .construction of slurry seals Published by Sabita Postnet Suite 56 Private Bag X21 Howard Place 7450 SOUTH AFRICA ISBN 978-1-874968-42-9 Published June 2011 . different test methods are applied, interpretation of the results has become difficult, requiring experience to .The Recommended Performance Guidelines for Emulsified Asphalt Slurry Seal and Micro Surfacing, ISSA A105 and A143, provide specific target values for cohesion results at 30 and 60 minutes. 2. Referenced Documents . 3.1 This test quantifies the time required before a slurry surfacing system may be subjected to straight rolling traffic. 4.

slurry seal design guidelines

In part one of our two-part series on the best practices of micro surfacing and slurry seal applications, we share all of the basics and best preparation practices. In part two, forthcoming in the Spring 2020 issue of Preservation Pro, will dig into the best practices on the job site. . “Test strips assure adequate workmanship, aesthetics .

construction of slurry seals Published by Sabita Postnet Suite 56 Private Bag X21 Howard Place 7450 SOUTH AFRICA ISBN 978-1-874968-42-9 Published June 2011 . different test methods are applied, interpretation of the results has become difficult, requiring experience to .TITLE: Outline Guide Design Procedure for Slurry Seal Download PDF . CODE: TB-112 TITLE: Method to Estimate Slurry Seal Spread Rates and to Measure Pavement Macrotexture Download PDF . CODE: TB-113 TITLE: Test Method for Determining Mix Time for Slurry Surfacing Systems Download PDF . CODE: TB-114 TITLE: Test Method for Wet Stripping of Cured .

8.1.2 Purpose of a Slurry Seal A slurry seal is a thin surface treatment that is laid in a thickness equal to the largest stone in the grading of its component aggregate. It may include either a conventional or polymer modified emulsion, and the slurry seal may be slow or quick setting. The emulsion is usually cationic in nature, but may be .SLURRY SEAL SURFACING. (REV 9-15-14) SECTION 335 SLURRY SEAL SURFACING 335-1 Description. . The cement mixing test shall be waived for this product. The polymer material shall be co-milled into the asphalt or added to the emulsifier solution prior to the emulsification process. The amount of polymer modifier shall not be less than 3.0% polymerCDPH Slurry Seal Product Related Media & Downloads. Warman WBH Range Conversions. Mining & Mineral Ore Double Slurry Seal. Mining company saves million AUD with AESSEAL system. AESSEAL system eases cost .5.4.7 Wet Track Abrasion Test—This test method covers measurement of the wearing qualities of slurry seal under wet abrasion conditions. NOTE 4—As a guide, slurry seal shall not show a loss of more than 75 g ⁄ft2. 6. Test Methods for Emulsified Asphalt Slurry Seal 6.1 Consistency Test: 6.1.1 This test method is used to determine the proper

slurry seal design and testing

The results of the sand patch test on WTAT samples showed that slurry seals made with RAP should be lightly rolled after lay-down to improve their friction life. Cost analysis indicates that the use of RAP as an aggregate .

Slurry Seal/Microsurfacing Testing Kit for use with the HM-459 Asphalt Pavement Analyzer in testing the performance of micro-surfacing and slurry seal mix designs for pavement preservation. This test kit comes with rectangular beam-type molds, rubber wheels, and software to collect and store test data on the user’s PC. Features: A comprehensive laboratory study was completed on the use of RAP in slurry seal by Saghafi et al. (2019) in which test results for a slurry seal mixture comprised of virgin aggregate were compared .

meteor package test

Abstract. With the increasing attention to preventive maintenance and rehabilitation of asphalt pavement, asphalt emulsions have gained popularity. Synchronous chip seal (SCS) and slurry seal (SS) are widely used in pavement preservation due to their low cost and efficiency but are not prevalent in new pavement construction, especially for airport pavement. .When design depth is reached, the slurry is displaced with concrete pumped through a tremie pipe to the bottom of the panel, and steel reinforcement is inserted. The finished walls can function as groundwater cutoff and soil retention systems during the excavation phase of the project and then as permanent underground walls with load-carrying .

Chip Seal A165 NOTICE . International Slurry Surfacing Association 800 Roosevelt Road Building C-312 Glen Ellyn, IL 60137 www.slurry.org . Failure to meet the specification for an individual test does not necessarily disqualify the system. If, for example, the system to be used on the project has a record of good .3. Wet Stripping Test-10 grams cured slurry in 400 ml. Moderately boiling water for 3 minutes. De cant and place on absorbent paper towel. Low asphalt retention can indicate lack of adhesion, low film coalescence, poor emulsion formulation, re-emulsification or possible false slurry. 3. Traffic/Cure Time by Slurry Cohesion testerapplications such as tack coats, prime coats, fog seals, slurry seals, chip seals, cape seals etc. Slurry seals are the most commonly used type of surfacing in South Africa. The function of a bitumen emulsion in a slurry seal is to bind the aggregate on the road and seal the underlying structural layers from moisture intrusion. Common slurry .

TB No. 113 Test Method for Determining Mix Time for Slurry Surfacing Systems . TB No. 114 Test Method for Wet Stripping of Cured Slurry Surfacing Mixtures . TB No. 115 Determination of Slurry System Compatibility . 2.2 ASTM Standards: .En este #inarTDM impartiremos los conocimientos fundamentales sobre la selección de los materiales, criterios de diseño y aplicación en obra del Slurry Seal. A liquid mixture of water and sand is recirculated via a slurry pump in order to make sure that a certain amount of sand (0.5%, 5000 parts per million, ppm) per volume of water is present uniformly at the contact interface. After each test the system is emptied of slurry and rinsed through with clean water to remove as many particles as possible.

asphalt slurry seal testing

asphalt slurry seal design

Build your project online in an easy and fun way using real pr.

test panels for slurry seals|asphalt slurry seal testing